“The key performance indicator data showed how some sites were performing better than others.” “Operations can learn from each other and can see what good practice looks like,” Maptek says.

“Recent graduates may be initially more comfortable with new systems, but longer-term players soon recognise the benefits of digital processes and quickly absorb them into a new integrated workflow,” it says.Īnglo American found continuous improvement is much easier when multiple sites are sharing the same system.

Maptek has found that other customers have a similar change management experience. “When an operation can see how others have overcome initial problems, uptake is faster,” Maptek says. “Maptek supports customers through BlastLogic configuration, training and implementation, aiming for minimal disruption to the production environment.”ĭr Tordoir paid particular attention to proving the benefits during the Anglo American rollout, mapping out the process and troubleshooting at the original sites so that replication was straightforward for subsequent sites.īenchmarked data was made universally available, so teams could track their adoption trajectory curve. “However good a new system is, the changeover phase can be disruptive,” Maptek says. “It enables operations to make blast implementation decisions with reference to mine plans, geology and geotechnical data with instant data connection and visualisation in the field or office,” Maptek says.Īnglo American, Maptek says, has found that design and execution teams have been brought closer together by using BlastLogic, while providing the data in a timely manner allows every level of the organisation to make proactive decisions. It is an all-in-one solution adding value to open-pit operations through streamlined drill and blast design, tracking and analysis. Data transfer between stages leads to further communication challenges between the field and office.īlastLogic stores a single source of truth for all processes, Maptek says, with the outcome being a significant increase in downstream productivity and better management of explosive risks. Traditional paper-based drill and blast processes are inefficient, complicated by multiple platforms contributing to design, hole placement and tie-up, according to Maptek. “It’s a really exciting time to be in the industry, with a lot of new technologies and processes emerging,” Dr Tordoir says. He benchmarked the original rollout of BlastLogic at six open-pit sites, which has enabled streamlined uptake at a total of 15 global locations so far, according to Maptek.

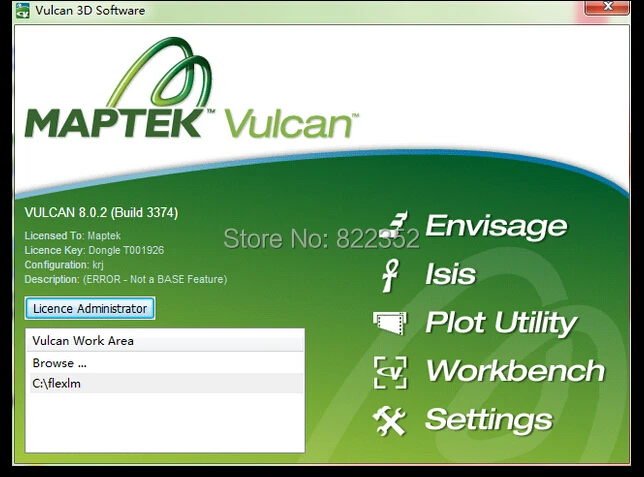

#Maptek vulcan user manual update#

In a Technical and Innovation update from May 2021, Anglo American reported a 50% improvement in drill and blast execution versus plan, which, it said, was enabled via real-time, in-field digital platforms.ĭr Alan Tordoir, Lead Drill & Blast Group Mining Technical & Sustainability for Anglo American, oversees drill and blast for 20 surface and 12 underground operations. The goal was to transform inconsistent practices into an integrated function underpinning safety and value protection. The miner commenced implementation of Maptek BlastLogic in 2017 to deliver the digitisation of critical drill and blast information.

#Maptek vulcan user manual software#

Maptek’s BlastLogic drill and blast software is helping Anglo American’s mines significantly improve its processes, the Australia-based company said in its latest Forge Newsletter.

0 kommentar(er)

0 kommentar(er)